Customization and tailor -made design of Gooseneck solutions for specific industrial needs

The modern industrial era requires not only efficiency and robustness in equipment but also exceptional adaptability to meet specific needs. The personalization of Gooseneck solutions embodies this necessity, offering unprecedented flexibility and optimized performance. Abeillon , a leader in this area, excels in the supply of tailor -made Gooseneck solutions that transform the complex requirements of customers in functional realities.

Understand specific industrial needs

Analysis of industrial challenges and the need for adaptation

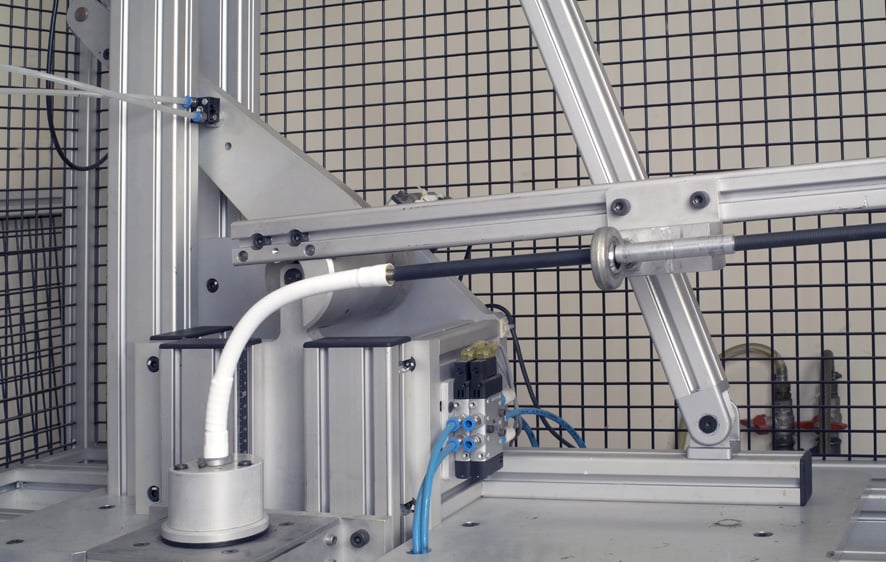

In industries ranging from automotive to aerospace , each sector has unique challenges that require specially suitable solutions. The rigidity of the standard flexibles can limit efficiency, hence the crucial importance of personalized Gooseneck solutions which integrate perfectly into existing systems while meeting the specific requirements.

Advantages of personalized solutions in the face of standard solutions

Unlike standard solutions, personalized abolions offer better integration and increased performance. By being designed specifically for specific applications, they allow better space management and optimization of industrial processes.

The personalization process at Abeillon

Steps of the tailor -made design: from the idea to the realization

The personalization process at Abeillon begins with a detailed analysis of customer needs, followed by the design and development of prototypes. This approach ensures that each solution is perfectly suited to the specific requirements of the customer.

The importance of close collaboration with customers

Abeillon firmly believes that the key to a successful solution lies in a close collaboration with his customers. This cooperation ensures that end products meet expectations exactly and improve the efficiency of industrial processes.

Technologies and materials used in personalization

Technological innovations and selection of materials

At Abeillon, technological innovation is at the heart of the design of personalized solutions, in particular thanks to the judicious use of materials adapted to each specific need for the customer. Materials such as copper steel, galvanized steel, stainless steel, and brass are carefully selected for their resistance, sustainability and compatibility with difficult industrial environments.

Adaptation and flexibility of designs

Abeillon 's personalized Gooseneck solutions are renowned for their adaptability. Whether for complex configurations or specific size requirements, Abeillon ensures total flexibility in the design.

Case studies: success ofAbeillon personalized solutions

Presentation of concrete cases of adaptation to specific needs

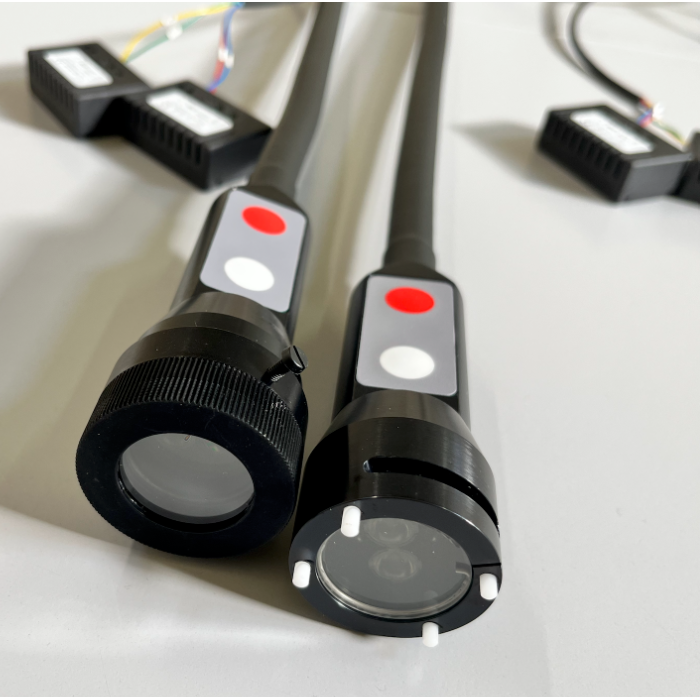

Case studies detail how Abeillon has managed to meet very specific needs in various sectors, illustrating the effectiveness of its personalized solutions. The company has developed tailor-made solutions for many customers and professionals, including adapted medical lamps, devices for people with disabilities, specific to the medical field, as well as personalized flexible micro-casks and card reading lamps specially designed for ships' command posts. These examples show how Abeillon adapts his innovations and his expertise to very diverse applications, meeting precisely to the requirements of each client.

Testimonials from customers and results obtained

The testimonies of satisfied customers, including renowned companies such as 3M, Volvo, Leonardo, and Thales , underline the positive impact of the personalized Gooseneck solutions of Abeillon . These returns highlight the significant improvement in industrial processes that our products have enabled, testifying to the confidence that these big names in the industry place in our tailor -made solutions.

The strategic importance of choosing personalized solutions

The long -term advantages of tailor -made solutions are undeniable. By choosing personalized solutions like those ofAbeillon, industries can not only meet their current needs but also easily adapt to future developments.

Why opt for Abeillon for your personalization needs

Opt for Abeillon means choosing a partner capable of transforming complex industrial challenges into effective and personalized solutions. By choosing personalization, you invest in the future and the continuity of your industry.

Our latest articles

Manufacturer of support solutions

We offer flexibles and supports adapted to multiple uses: medical, audio, industrial, military and much more.

ABEILLON

The European leader in semi -rigid flexible solutions

Design assistance

Abeillon accompanies you at each stage, from the definition of your needs to the complete realization of your project.

International certifications

ABEILLON is ISO 9001: 2015 certified and referenced with NATO under code F9963.

French manufacture

ABEILLON implements, on its production site based in IDF, all the manufacturing processes allowing it to make a wide variety of flexible supports.

Great logistics flexibility

Our teams industrialize, manufacture and send flexible supports worldwide, ranging from the single piece to several thousand units per lot, with an annual production capacity of around 150,000 pieces.