Embase d’antenne : le support d’antenne militaire

Abeillon designs and manufactures flexible antenna mounts. This state-of-the-art equipment provides support, spatial orientation, and mechanical protection for mobile omnidirectional antennas.

Flexible antenna mount

The role

These antenna mounts are specifically designed for the following frequency ranges:

- VHF. The Very High Frequency band. More specifically, the portion of the radio spectrum extending from 30 MHz to 120 MHz.

- and UHF. The ultra-high frequency band, or even microwaves. And more specifically for the band of the radio spectrum between 300 MHz and approximately 5 GHz.

These bases provide the mechanical and electromagnetic interface between a radio transceiver and a military antenna . Depending on their configuration, they also allow connection between a support structure of a ground intervention vehicle and an antenna.

An antenna base in detail…

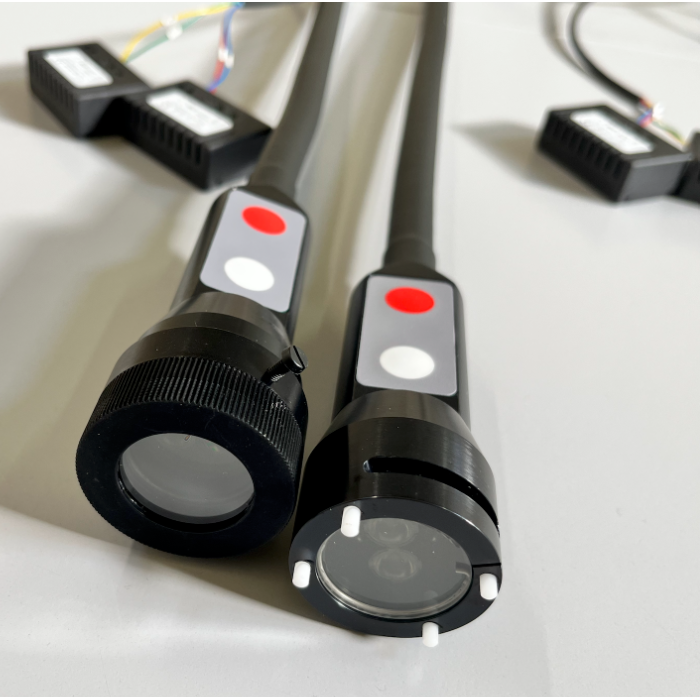

In the VHF frequency range, the antenna mount features mechanical and electromagnetic conduction interfaces with a tapped hole at their base and a threaded rod at the top. For use with a mobile radio, the base can be fitted with a BNC connector.

The central section consists of a semi-rigid, flexible gooseneck tube. This tube can optionally be reinforced. This type of mount thus provides the desired spatial orientation for the antenna and protects it against impacts.

In the case of a VHF antenna mounted on a vehicle, the central part of the antenna support consists of:

- of a flexible but shape-memory-free composite mechanical assembly,

- or a spring of straight or conical shape with tightly wound coils.

Thus, these types of supports provide mechanical protection for the antenna in case of collision with an obstacle.

In the UHF frequency range, antenna mounts feature N, NP, BNC, and SMA type electrical connectors at their ends.

The central section consists of a semi-rigid, shape-memory flexible cable. This component becomes essential when the mount's primary functions are to provide spatial orientation for the antenna and protect it from impacts.

In the specific case where the UHF antenna is to be mounted on a land vehicle, the mount is equipped with one of the aforementioned connectors, located at the top, for connecting the antenna.

Construction of a base

The section of the support located below the connector can consist of one or two flexible, shape-memory sections.

These two flexible sections are separated by a rigid element. The rigid element's primary function is to position the antenna at the correct height on the vehicle.

The lower flexible element, connected to a mechanical interface bolted to the vehicle, protects both the antenna and the rigid riser element from impact.

The upper flexible element, interfaced with the antenna connector, protects only the antenna. The connecting cable between the radio module and the antenna runs inside the support.

The antenna mounts are covered with a rubber or polyethylene sheath. This covering provides protection against the harsh environments typical of operational fields, while also adding a significant aesthetic touch to all or part of the mount, allowing it to blend into a specific environment.

The entire antenna support , including the rubber or polyethylene coating, is painted in the color requested by the customer, depending on the field of operation. The color may include: NATO green, desert sand, or black.

The selection of materials, combined with manufacturing processes designed and implemented by ABEILLON, enables the production of antenna mounts resistant to harsh environments. They also feature the ability to withstand a static load in a fixed spatial position while maintaining their mechanical properties, even after a high number of flexing cycles.

We can add markings to the sheath at the customer's request. The only requirement is that our customers provide us with their text or design.

Abeillon, a French company supplying equipment to NATO industries

Our industrial site has a fleet of machines dedicated to:

- the manufacture of springs,

- the manufacture of semi-rigid flexible ,

- the implementation of several cutting and end preparation processes,

- assembly by crimping or welding

and places particular importance on the finishing of products through the implementation of painting, sheathing, and marking processes.

Our highly skilled and experienced staff manage these manufacturing facilities on a daily basis. Production capacity extends to 200,000 parts per year across all sectors, thanks to robust manufacturing processes.

ABEILLON offers a wide range of antenna mounts from a comprehensive database of existing products. The company

The engineering team is responsive to customer needs, adapting existing product designs or developing entirely new ones to meet the specific requirements of each application.

Our latest articles

Manufacturer of support solutions

We offer flexibles and supports adapted to multiple uses: medical, audio, industrial, military and much more.

ABEILLON

The European leader in semi -rigid flexible solutions

Design assistance

Abeillon accompanies you at each stage, from the definition of your needs to the complete realization of your project.

International certifications

ABEILLON is ISO 9001: 2015 certified and referenced with NATO under code F9963.

French manufacture

ABEILLON implements, on its production site based in IDF, all the manufacturing processes allowing it to make a wide variety of flexible supports.

Great logistics flexibility

Our teams industrialize, manufacture and send flexible supports worldwide, ranging from the single piece to several thousand units per lot, with an annual production capacity of around 150,000 pieces.