Antenna base: military antenna support

Abeillon designs and manufactures flexible antenna supports. This cutting -edge equipment provides support, spatial orientation and mechanical protection of mobile omnidirectional antennas.

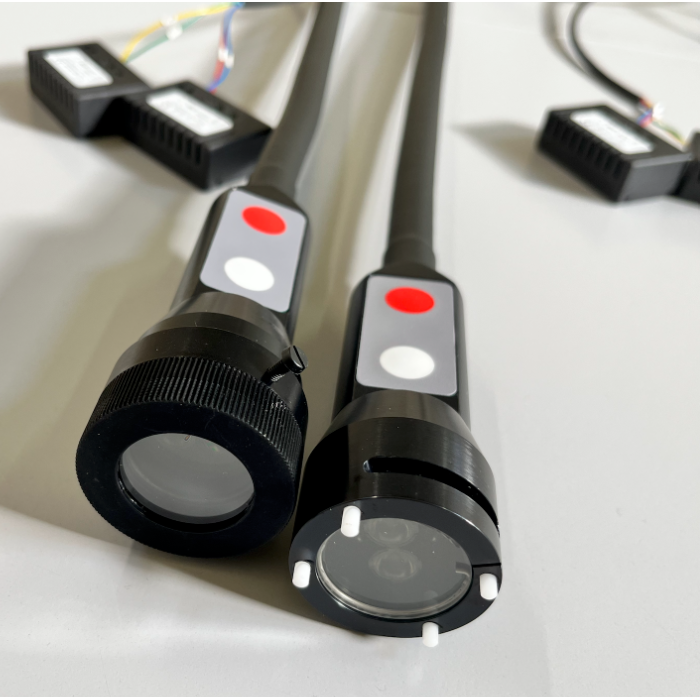

Flexible antenna support

The role

These antennae supports are specially designed for frequency ranges:

- VHF. The band of very high frequencies (Very High Frequency). And more specifically for the part of the radio spectrum extending from 30 MHz to 120 MHz.

- and uhf. The strip of ultra high frequencies (Ultra High Frequency), even hyperfrequency. And more specifically for the band of the radio spectrum between 300 MHz and around 5 GHz.

These steps ensure the mechanical and electromagnetic interface between a radio issuer and a military antenna . Depending on their configuration, they also allow the connection between a structure carrying a land intervention vehicle and an antenna.

A antenna base in detail ...

In the VHF frequency range, the antenna support includes mechanical and electromagnetic conduction interfaces fitted with a hole tapped at their base and a threaded rod at the head. In the case of a link with a mobile radio station, the base can be equipped with a BNC type connector.

The central part is made up of a semi-rigid memory flexible in shape. This Gooseneck Tube can possibly be reinforced. Thus this type of support gives the desired spatial orientation to the antenna and protects it from shocks.

With regard to a VHF antenna on a vehicle, the central part of the antenna support is formed:

- of a flexible composite mechanical set but without memory of form,

- or a spring of straight or conical shapes to joint turns.

Thus these types of supports ensure mechanical protection of the antenna in the event of a collision with an obstacle.

In the UHF frequency range, the supports have electrical connectors of type N, NP, BNC, SMA at their ends.

The central part is made up of a semi-rigid memory flexible in shape. This component becomes essential as soon as the main functions of the support are to give a spatial orientation of the antenna and to protect it from shocks.

In the particular case where the UHF antenna must be embarked on a land vehicle, the support has one of the connectors indicated above, located in the upper part to connect the antenna.

Constitution of a base

The part of the support located below the connector, can be made up of one or two flexible stages and without memory memory.

The two flexible stages are separated by a rigid element. Whose essential function is to position the antenna at the altitude that suits the vehicle.

The lower flexible element, connected to a bolted mechanical interface on the vehicle, has the function of protecting against collision shocks both the antenna and the rigid booster element.

The higher flexible element interfaced with the antenna connector, has the function of protecting the antenna only. The link cable, between the radio module and the antenna, passes inside the support.

Antennae supports are coated with a rubber or polyethylene sheath. This dressing provides both protection against aggressive environments characteristic of operating fields. While adding a significant aesthetic aspect, to all or part of the support to fit into a specific environment.

The entire antenna support , including the rubber or polyethylene coating, is painted the color requested by the customer according to the operating field concerned. The shade can in particular be: green "NATO", or "Sand of the desert", or black.

The selection of materials combined with manufacturing processes designed and implemented by ABEILLON, allow the production of branches resistant to severe environments. Added to the characteristic of supporting a static load in a fixed spatial position with maintenance of mechanical properties, even after a high number of cycles of flexions.

We carry out, at the request of the customer, a marking on the sheath. The only constraint, whether our customers provide us with their text or drawing.

Abeillon, French company supplier of NATO equipment manufacturers

Our industrial site has a machines park dedicated to:

- the manufacture of springs,

- the manufacture of semi-rigid flexible ,

- the implementation of several cutting and preparation processes,

- assembly by crimping or welding

And puts particular importance to the finishing of products by implementing paint, sheathing, and marking process.

Our qualified personnel with great pilot know-how on a daily basis these manufacturing means. The production capacity extends up to 200,000 parts per year, all areas combined, and thanks to robust manufacturing processes.

Abeillon ABEILLON branch supports from a large database of existing products. It designs, manufactures and also distributes new products corresponding to the latest technological developments in radio communication.

The engineering team is attentive to its customers. It adapts the design of existing products or designs new products that meet the specifics of each use case on the field of operation.

Our latest articles

Manufacturer of support solutions

We offer flexibles and supports adapted to multiple uses: medical, audio, industrial, military and much more.

ABEILLON

The European leader in semi -rigid flexible solutions

Design assistance

Abeillon accompanies you at each stage, from the definition of your needs to the complete realization of your project.

International certifications

ABEILLON is ISO 9001: 2015 certified and referenced with NATO under code F9963.

French manufacture

ABEILLON implements, on its production site based in IDF, all the manufacturing processes allowing it to make a wide variety of flexible supports.

Great logistics flexibility

Our teams industrialize, manufacture and send flexible supports worldwide, ranging from the single piece to several thousand units per lot, with an annual production capacity of around 150,000 pieces.